|

Hydroweave®

can be used for a wide range of applications. These studies

detail various tests that have been performed on Hydroweave®.

Wear and Use Testing

AquaTex commissioned Auburn University to study the cooling

properties of Hydroweave®. The research project evaluated

how long Hydroweave® remains active and how effectively

it cools the wearer. Auburn University is a member of the

National Textile Center and conducts performance testing

on garments and their effects on the wearer under various

simulated work and stress conditions.

How long does it perform?

Cooling times vary with the application and the environment.

In environments where the qualities of active evaporation

can be realized, Hydroweave® can cool for hours. The

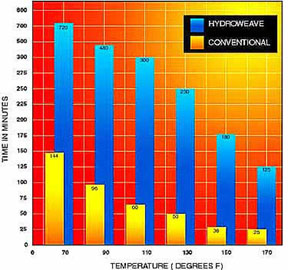

chart characterizes testing by Auburn University of Hydroweave®'s

evaporative cooling times to that of a conventional fabric

at varying temperatures from 70°F to 170°F (21~76º

C). In this test, Hydroweave® was shown to cool an outstanding

125 minutes (2 hours and 5 minutes) at 170°F.

Hydroweave® was also proven effective as a passive heat

sink for fully enclosed applications. In tests, vests made

from Hydroweave® were worn beneath poly-coated encapsulation

suits and proven as an effective deterrent to heat stress,

increasing work time by an average of 16.4%.

Expected performance of BodyTeq Apparel The cooling performance

of BodyTeq Apparel will depend on the following:

1. The length of time the Hydroweave® core absorbed

moisture.

Refer to Activation Procedure for specific products. Hydroweave

will absorb water for up to five minutes, but additional

time may be recommended if wicking is required to evenly

distribute moisture.

2. Humidity.

Higher humidity will slow evaporation, producing less cooling,

but over a longer duty cycle.

3. Temperature.

Higher air temperature will increase evaporation. On still

days, the initial sense of cooling may lessen as the body

adjusts to the cooling affect. However, the garment continues

to remove heat, and its contribution is dramatically felt

if the wearer moves into an air conditioned environment.

4. Wind speed over the garment.

Higher wind speed increases evaporation and cooling. On

motorcycles, vehicles, or bicycles, leather jackets or windbreakers

may be worn over the garments and opened to regulate cooling.

Based on these parameters, expect cooling from 1.5 hours

on a motorcycle or vehicle on a hot dry day, to as much

as 5 hours walking on a more humind day with less wind over

the garment.

How effective is Hydroweave®

when used under a barrier suit?

Used in a passive 'heat-sink' mode, Hydroweave® has

been proven to effectively reduce heat, maintain lower core

body temperature and increase worker productivity for up

to 16.4%....

read more

Cooler Fabrics For Protective

Apparel

For years, the apparel industry has focused on material

technology for fabrics that offered greater protection while

also becoming lighter, thinner, and more flexible....

read more

|